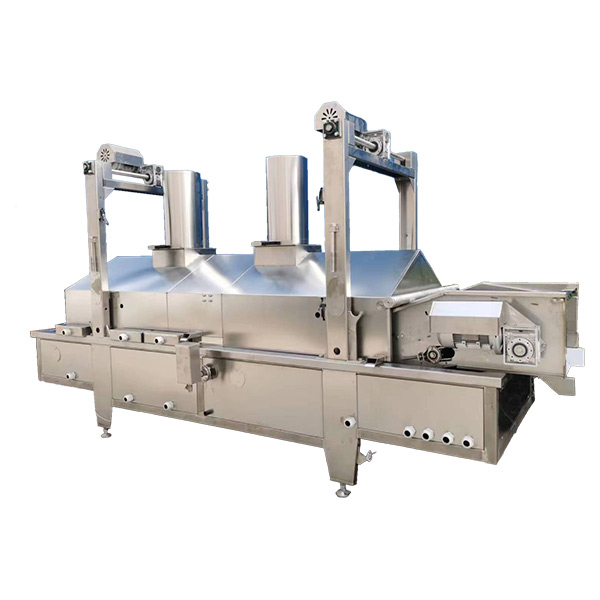

Suitable for the processing of puffed and floating products. The fully automatic fryer production line is composed of a complete set of equipment including raw material mixing system, extrusion puffing system, frying system, fried oil treatment system, oil draining system, seasoning system, cooling system, distributing system, packaging system, and centralized control system. This achieves fully automated production operations for puffed products.

For Large-scale Manufacturers with Batch Production

Applicable Foods: Rice crisps, sachima, egg yolk puffs, golden beans, meats, fish, green peas, coated peanuts, etc.Features: High degree of automation for batch production, labor-saving. Automatic temperature control, automatic slag removal, automatic filtering, automatic oil replenishment, leakage protection, safe operation.Heating Methods: Electric, natural gas, liquefied petroleum gas, coal, thermal oil, diesel.